Q&A INDEX

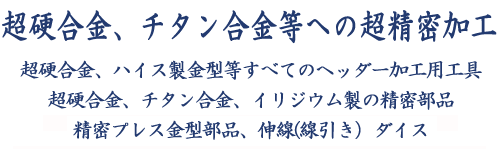

1.Our processing technology

Q:What is your superior metal

A: Tungsten Carbide, High Speed Steel and Titanium alloy.

Dies steels like SKD etc, we are good too but there are

many manufacturers who are good at those materials.

Iridium, there are not many orders but we are good with it.

I think not so many manufacturers are good at Iridium.

We are eager to challenge precision processing research of difficult material or expensive material which our competitors are reluctant to do. Please feel free to consult with us.

We are not superior to process stainless steel which is said easy, generally.

Q:Process available work figure?

A:Cylindrical is the most superior as it is a header dies punch figure but manufacturing many variety of figures like rectangular.

Q:Hole process?

A:Superior to precise and odd-shaped hole processing.

Although it relates also depth but generally minimum φ0.1 millimeter, maximum 16 millimeters are available.

Q:Do you accept a partial contract processing?

A:Depending upon the contents but fundamentally we accept.

2.Heading Dies

Q:Lead time

A:Basically 2-3 weeks, about heading dies.

We will try best to comply with your urgent needs.

If we have a material stock, shortest 4-5 days.

Re-work of cutting groove punch (punch for rivet and contact),

shortest would be 2 days.

A:A price of header dies differs depends on material, size, shape and requested accuracy.

For example, dies for small fasteners would cost \8,000~\25,000.

Set dies structure cost normally \25,000 up.

In case of production of complicated figures, it is a our know how to decrease a number of dies.

As a result, sometimes even single piece die price would be expensive, total cost can be cheaper. Please feel free to consult with us.

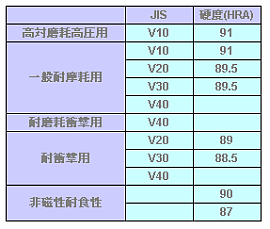

A:Life time differs depends on die material, product material, processing level and speed etc.

In the case of micro fastener production by Tungsten carbide, there are cases several tens million pieces can be manufactured by one die.

In case of small fastener production, normally several million pieces can be manufactured.

It is informed by our Chinese customer that our dies for screw production, life is about 2~3 times of Chinese dies. We guess a reason of such a big difference is a lapping process.

By learning customer’s using environment, we are trying best to propose how to improve a life of dies.

Please feel free to consult with us.

Q:Can we order a die for Titanium fastener?

A:Titanium is a difficult material to process but Titanium fastener becoming popular.

We are manufacturing many dies for Titanium ・ Titanium alloy screw.

If you show us your drawing, we are pleased to propose the best dies material and structure for you.

Q:Repair of Dies?

A:Yes, we do. But in case of other company’s product, depend on repair contents, sometimes physically not possible which please understand.

Q:Coating on dies

A:We use subcontractor for coating.

The most suitable coating will be selected following to your requirement.

Q:If we show the product which we want to produce, can you design all necessary dies?

A:Yes, we can. We will quote designing charge in advance.

Q:Can we order many tools which are used at header process?

A:Almost all tools like, header dies, punch, knife, cutting die and KO pin

are sold.

We also sell gages which are needed to measure fastener holes.

Q:We are looking for somebody to manufacture difficult shape parts and fastener.

Could you introduce someone who is the most appropriate among your customers?

A:We are working with about 100 header process manufacturers.

We have about 20 overseas customers.

We are pleased to introduce the most suitable manufacturer if you inform your necessary product and quantity.

We do not charge any introduction fee so please inquire us feeling free.

3.Rolling Dies

Q:Can I consult with you about rolling dies?

A:Yes, we are a sales representative of 『Kobata Iron Works』 Please leave it to us.

4.Press Die Parts

Q:Can you respond any of the press die parts?

A:Our superiority is the die made of difficult process materials Like Tungsten carbide and highspeed steel.

If you are planning to process hard materials and enhance anti shock capability or improve wear resistance, we hope we can be of any help.

We can propose a selection of die materials.

We are very confident about process technology but in comparison with press process specialized company our know how of press process is still on the way.

Please take note the best would be customer design the dies by themselves.

5.Wire Drawing Dies

Q:Can you process any kind of wire drawing dies?

A:We understand we are available for dies which needs special high level of impact resistance and wear resistance or dies need special high accuracy.

In the case of standard wire material like steel, it is said there are many manufacturers who can offer much cheaper prices.

1.Internship

Q:You are accepting Internship every year.Which kind of students can be covered?

A:The students are university or master’s degree students.

As our activity is manufacturing by machinery, the science course students are objected but anyone who has interest about metal processing technology would be welcome.

Q:Timing of Internship?

A:Many students want to utilize summer holiday, so main season would be July to September but any timing as far as we can manage we accept. Please contact.

Q:Period of Internship?

A:We consider one unit is one week.

If you have clear target, we will accept a longer period.

If many applicants in one time, we may arrange two days short factory tour which students can touch and practice machine and dies if we are available.

2.Factory Tour

Q:Do you accept a factory tour?

A:Yes, we do.

We accept elementary and middle school pupils who has full of curiosity.

Every year we can welcome many elementary school pupils living nearby.

But there might be not convenient day so please apply one week before for sure.

Q:Do you participate Summer Saitama Monozukuri Stamp rally?

A:Since 2011, we are participating it and will continue from now on.

Details, please refer pamphlet of stamp rally or check with Saitama prefecture home page.

Any questions besides above, please feel free to contact.

You may inquire by e-mail.

Please fill our below frames and push 『Transmit』button.

We will reply later to you.

Any questions besides above, please feel free to contact.

You may inquire by e-mail.

Please fill our below frames and push 『Transmit』button.

We will reply later to you.

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」