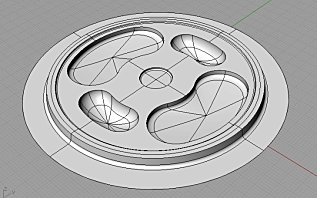

The sample of Umbond Shaped Punch

- Work Material:G6

- Processing Machine : Precision Micromachining Center

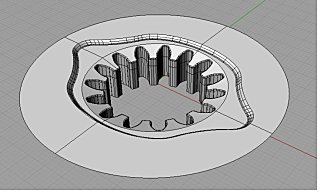

- Processing process : Not shaping by the sinker electrical discharge machining, direct carving on the salient & engraved portion and process on the waste portion by cut out tool

- Processing Time:About 40h in a row

[Special Note for the Sample]

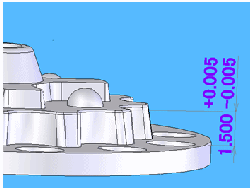

1.The margin of diameter among 12 engraved were±0.0011mm.

Actual size was 1.4967mm for the Intentional level of 1.5000mm(margin of 3.26μ)

Used each of two kinds of toll

Succeeded to processing the super accurate configuration which has been barely worked out since it was difficult to stabilize the accuracy due to reducing down of grinding stone only by grinding process.

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」