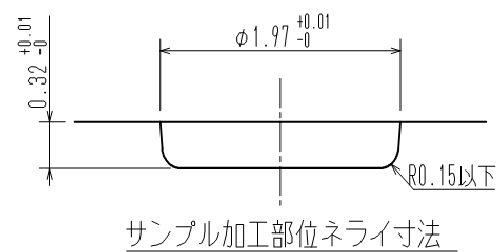

・Work Material:Fine-gained WC-Co, G5, G6 etc.

・Processing Machine:Precision Micromachining Center

(Not shaping by the sinker electrical discharge machining )

・Mirror finish with Lap-less

Roughness of the bottom:Ra 0.020μm(same as lapped finish)

【Difference from Existing Processing】

1.Reduce its processing time substantially and 24h in a row

[Processing time per piece] Existing Process:Sinker electrical discharge machining + Turn out the electrode + lapping = 50 minutesNew Process :Direct carving =15 minutes

*Available mass-production of greater than 1,000 units Series processing of 30 units per a lot

2.Ensured Substantial Cost-cutting

Its running cost would be 1/5 to 1/10 of the existing process

3.Delivered its quality improvement

No hardening layer nor micro-crack as the electrical discharge machining

Maximize its potential of the WC-Co

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」