1.Introduction

In 2011 as the world’s first manufacturer, our company have succeeded in mass production of the die and punch by direct carving to WC-Co (carbide)

We think it might be seemed by the most people that what point is the world’s first. The WC-Co (carbide) is extremely hard as recognized in using for tools and the die and punch to process the normal metal. As we state in the section of “Electrical Discharge Machining to the WC-Co (carbide)”, in order to cut and machine the WC-Co (carbide), traditionally said “Although by using the very expensive special machining center with the particular edged tool, it’s barely able to process in the real world, and its configuration and the degree of accuracy could be remain limited.”

As the result, it was our business common sense that the processing to the WC-Co (carbide) should be done by the Electrical Discharge Machining.

Our company has been setting our objective and investigating for mass-production of WC-Co (carbide) die and punch in a low cost way. Then finally, we could achieve to our goal through its upgrading of metal cutting machine and tool.

2.Mass Production of Die to the WC-Co(carbide)by Direct Carving

・Work Material:Fine-gained WC-Co (carbide), G5, G6 etc.

・Processing Machine:Precision Micromachining Center – (Not shaping by the sinker electrical discharge machining)

・Mirror finish with Lap-less – Roughness of the bottom:Ra 0.020μm(same as lapped finish)

[Difference from Existing Processing]

1.Reduce its processing time substantially and 24h in a row

[Processing time per piece]Existing Process:Sinker electrical discharge machining+Turn out the electrode+lapping=50minutesNew Process :Direct carving =15minutes※Available mass-production of greater than 1,000 unitsSeries processing of 30 units per a lot2.Ensured Substantial Cost-cutting

Its running cost would be 1/5 to 1/10 of the existing process

3.Delivered its quality improvement

No hardening layer nor micro-crack as the electrical discharge machining

Maximize its potential of the WC-Co (carbide)

![]() Reproduction of Dies and punches

Reproduction of Dies and punches

Processing of Super Precision Components by Direct Carving to WC-Co (carbide)

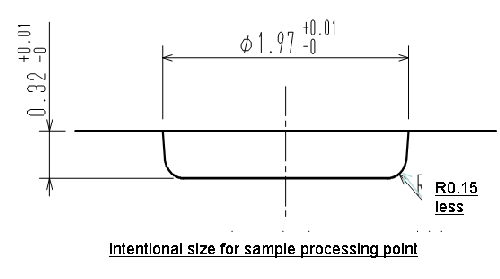

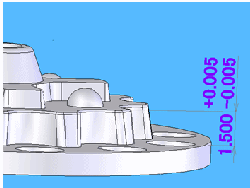

The sample of Umbond Shaped Punch

*Work Material:G6

*Processing Machine : Precision Micromachining Center

Not shaping by the sinker electrical discharge machining, direct carving on the salient & engraved portion and process on the waste portion by cut out tool

*Processing Time:About 40h in a row

[Special Note for the Sample]

1.The margin of diameter among 12 engraved were±0.0011mm.

Actual size was 1.4967mm for the Intentional level of 1.5000mm(margin of 3.26μ)

Used each of two kinds of toll

Succeeded to processing the super accurate configuration which has been barely worked out since it was difficult to stabilize the accuracy due to reducing down of grinding stone only by grinding process.

2.The Mirror Finish by Lap-less

Roughness (Ra) 0.0314μm

3.Ensured Substantial Cost-cutting

Its running cost would be less than

1/10 of the existing process

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」

Tungsten Carbide Cold Heading Dies and Punches-TOKYO BYORA KOKI Co.,Ltd. original Tungsten Carbide die 「Tokyo-ACE 」